Why Some Solar Modules Fail Faster Than You Think?

September 10th, 2025

Solar modules are expected to last decades, yet one of the most common causes of underperformance often goes unnoticed: micro-cracks. Invisible to the eye and detectable only under electroluminescence (EL) testing, these tiny fractures in the cell structure can quietly erode power output, shorten system lifespans, and even increase fire risk. For EPCs, installers, and asset owners, hidden cracks represent both a technical and financial liability.

The Hidden Risks of Micro-Cracks

Cracks can form at multiple stages—manufacturing, transportation, installation, and long-term operation under mechanical load. Their effects are severe:

- Power loss: fractures disrupt current flow, reducing generation.

- Leakage currents: silicon residues at the fracture edges may trigger local short circuits.

- Cell breakage: weakened areas are more vulnerable to external stress, leading to visible cracks or open-circuit failure.

- Hot spots & fire risk: damaged regions heat unevenly, accelerating aging and raising safety concerns.

While no solar technology is immune, some designs are more prone to cracking than others.

Why TOPCon Faces Higher Risk

TOPCon has gained traction as a mainstream technology, but its very design makes it more vulnerable to hidden cracks:

- Thinner wafers: to cut costs, TOPCon cells are often made with silicon wafers below 130 µm. The thinner the wafer, the lower the mechanical strength, and the higher the chance of cracks during handling or stress.

- Complex rear layers: TOPCon’s ultra-thin tunneling oxide layer and polycrystalline silicon layer expand and contract differently from the wafer, creating localized stress during thermal cycles.

- Silver paste and soldering strain: traditional silver-based metallization and “Z” type soldering concentrate mechanical stress at the cell edges. Combined with high soldering temperatures, this raises the likelihood of fractures.

- Weaker stress absorption: compared to designs with thicker glass or advanced interconnection methods, standard TOPCon modules are less effective at dispersing mechanical loads such as wind pressure or hail impact.

In short, the race for efficiency has introduced structural compromises that can undermine reliability.

A Different Path: N-Type ABC

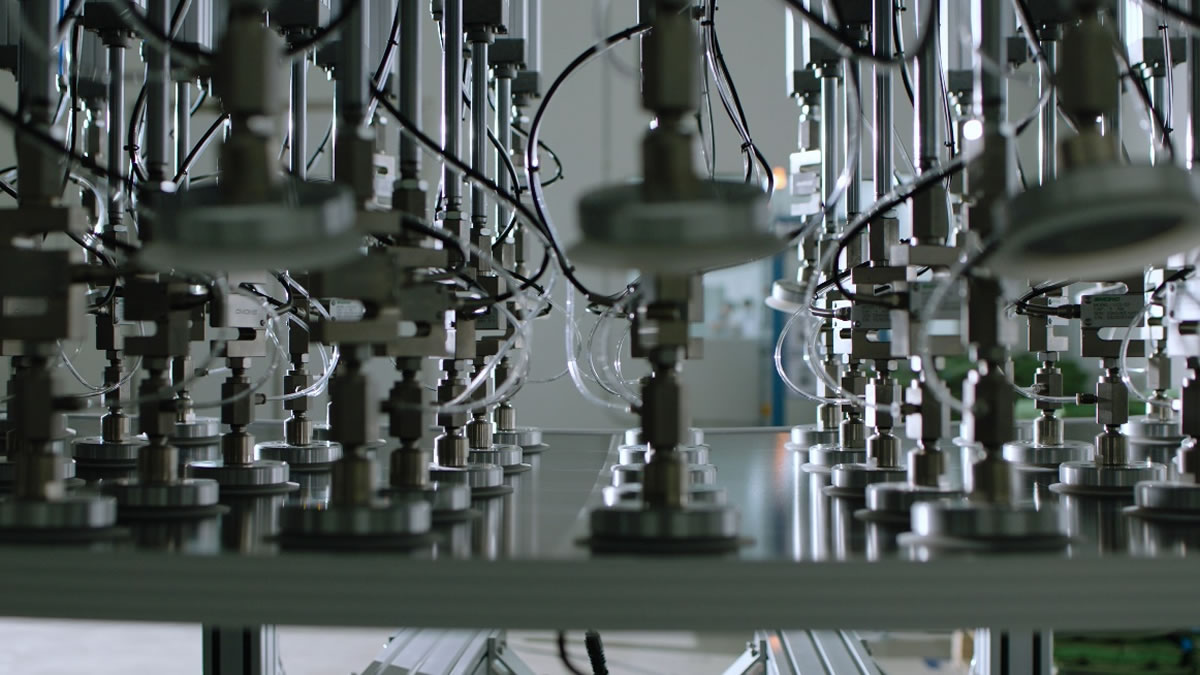

Not all high-efficiency technologies come with the same trade-offs. AIKO’s N-Type All Back Contact (ABC) architecture addresses the crack challenge at its root:

- Robust copper interconnection replaces silver paste, avoiding brittle joints and reducing stress points.

- Optimized mechanical resilience ensures stronger load-bearing capacity, maintaining integrity under transport, installation, and decades of operation.

- Better temperature coefficient limits thermal stress, securing stable generation even in hot climates.

For EPCs and asset owners, this means fewer risks of hidden cracks, more stable long-term output, and better return on investment.

As the solar industry scales, durability is becoming as important as peak efficiency. Technologies that minimize hidden crack risks will define which projects truly deliver their promised lifetime yields. The industry has seen that not all high-efficiency modules perform equally under real-world conditions.

By rethinking cell structure and interconnection, ABC technology demonstrates that it is possible to combine high efficiency with long-term reliability—a foundation the solar transition cannot afford to overlook.