AIKO’s N-Type ABC PV Modules Deliver Unmatched Reliability, Reducing Microcrack Risk by Over 60%

October 23rd, 2024

Even in the mature photovoltaic (PV) industry market, microcracks remain as a persistent and significant challenge, often referred to the “invisible killer” of PV modules. Silicon PV cells are inherently fragile, mishandling during production, transportation, installation, or maintenance can easily lead to microcracks, result in substantial power loss. In severe cases, can cause hotspots, leading to further damage. A search for “microcrack resistance” in HimmPat, a third-party patent database, reveals over 219 patents related to this issue, highlighting the intense effort PV companies are making to combat this challenge.

AIKO, a top-ranked solar technology leader with BloombergNEF Tier 1 status, has developed a comprehensive solution to address the problem of microcracks in its N-Type ABC PV modules. Through a combination of advanced single-sided welding, silver-free metallization coating, and optimized tensile design, AIKO significantly reduces the risk of microcracks, ensuring high reliability and durability for its modules.

Eliminating Silver Dependency: Enhanced Module Toughness

Traditionally, silver has been an indispensable electrode material in PV cell production. However, the combination of silver element and vitreous body in traditional PV cell manufacturing creates a loose, unstable structure, which increases the likelihood of microcracks. AIKO’s proprietary silver-free technology uses pure copper element to bond with the silicon wafer, significantly enhancing the mechanical strength and flexibility of the cells, thereby reducing the risk of microcracks.

Moreover, unlike traditional silver paste printing processes that required high-temperature sintering—which can damage the silicon wafer lattice—AIKO’s silver-free metallization technology maintains the integrity of the wafer, further minimizing the risk of microcracks.

This innovation not only improves the module’s resistance to microcracks but also substantially reduces the high costs associated with silver usage, ensuring a more sustainable and cost-effective production process.

Straight-Line Welding: Reducing Stress on Cell Edges

AIKO’s N-Type ABC PV cells feature a unique back-contact design, allowing for straight-line welding rather than the traditional zig-zag pattern. This design places all interconnecting ribbons on the backside of the cells, avoiding the multiple stress points that can cause microcracks in traditional welding techniques.

In contrast to the traditional zig-zag pattern, which applies uneven force across the cell surface and edges, AIKO’s straight-line welding ensures a more uniform distribution of force, reducing the likelihood of microcracks. Additionally, the ribbons used in AIKO’s PV modules are significantly wider than those in other mainstream products, further enhancing their tensile strength and reliability.

Proven Durability Under Extreme Conditions

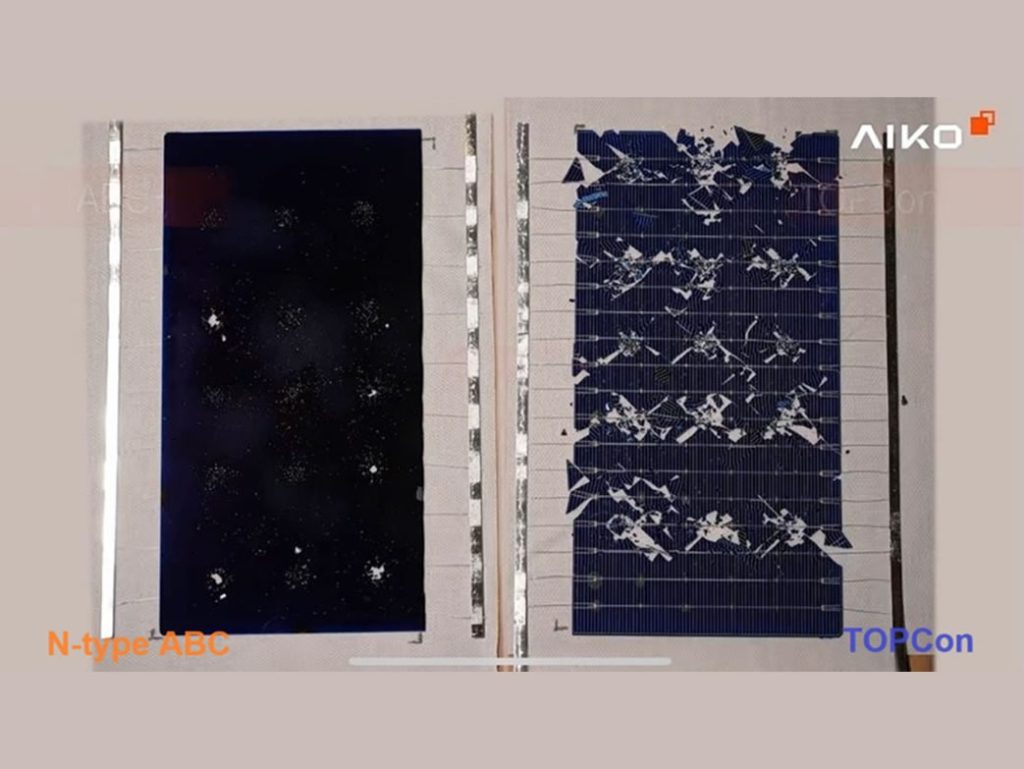

AIKO’s N-Type ABC PV modules are not only designed to resist microcracks but also to perform reliably under extreme conditions. At SNEC and Intersolar 2024 exhibition, AIKO demonstrated the superior impact resistance of its modules in live. In the experiment, under a mechanical impact of 2 kg at 1.1 m/s, TOPCon cell is largely shattered, with extensive cracking spreading outward from the point of impact, resulting in a current loss of up to 44,61%. In contrast, the N-Type ABC cell under the same conditions only exhibited fractures at the point of impact, current loss 16,48% only. Additionally, the coated electrodes remained tightly connected to the cells without disintegration.

In recent years, extreme weather events such as heavy rain, snowstorms, and hail have become more and more frequent. To simulate the effects of various unforeseen disasters, AIKO’s testing center employed mechanical load testing equipment to replicate the extreme scenarios. After simulated wind and snow tests, the EL images showed that AIKO N-Type ABC PV module’s degradation and microcrack rate were both below 0,5%, with a microcrack rate significantly lower than traditional modules, and the cell bending strength exceeded traditional cell by more than 20%.

A Commitment to Quality and Innovation

From production to installation and beyond, AIKO’s N-Type ABC PV modules are engineered to minimize the risks associated with microcracks. However, the most crucial factor in ensuring the long-term performance of these modules is their inherent quality. As the PV industry continues to evolve, PV manufacturers must focus on providing highly efficient, stable, and reliable products to maximize customer returns. AIKO remains committed to pushing the boundaries of PV technology, delivering top-tier products that offer unmatched value to its customers.