Global PV Leaders Convene to Define

the Next Era of BC Technology

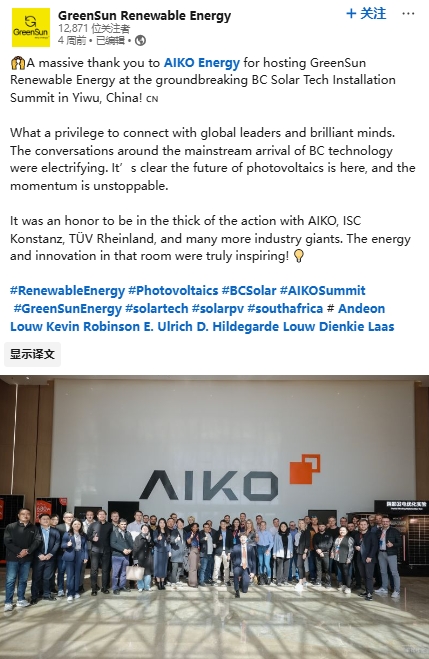

Yiwu, China, November 25, 2025 – The global solar industry experts converged in Yiwu for the landmark Global BC Tech Innovation Summit and the 14th bifi PV Workshop, held successfully on November 24-25. Co-organized by International Solar Energy Research Center Konstanz (ISC Konstanz) and AIKO, the summit attracted over 600 leading research scholars, technical experts, and top managers from prominent PV companies and institutions worldwide, marking a significant milestone in the advancement of back contact (BC) technology.

The bifiPV Workshop, a premier global academic summit for the PV industry, has a history of fostering high-level dialogue in locations including Konstanz, Amsterdam, Denver, and Doha. Following its 2024 edition in Zhuhai, this year’s event returned to China, specifically to Yiwu, a hub for advanced BC cell and module manufacturing, to inaugurate a new chapter in BC technology development.

Summit Agenda

09:30 – 11:00

1.Welcome and opening

Welcome Speech

Yiwu Municipal Government:Jianhua Mao

Welcome Speech

CPIA:Yiyang Liu

Cofounder and Director of ISC Konstanz:Radovan Kopecek

N-Type ABC Technology – Leading Humanity into the Carbon-Free Era

Chairman of AIKO :Gang Chen

11:00 – 12:30

2. BC tech Roundtable Forum

Roundtable Forum

TaiyangNews Min Ge 、Chief Scientist of AIKO:Yongqian Wang 、 LONGi: HongBo Tong 、Prof. Dr. Peter Fath、 Dr. Gianluca Coletti

12:30 – 14:00

Lunch

14:00 – 15:00

3. High quality material, ingot production

Executing Overseas Ingot & Wafer Factories at Industrial Scale

Founder & CEO, RCT Solutions GmbH:Prof. Dr. Peter Fath

Trends For FBR Granular Polysilicon Technology

Deputy Director of GCL TECH Global R&D Center for Silicon Materials:Dr. Liu Tao

15:00 – 16:00

Break

16:00 – 17:30

4. Bifacial BC cell R&D

ISC Konstanz :Lejo Joseph Koduvelikulathu

UNSW:Jessica Yajie Jiang

Technical Director of AIKO:Kaifu Qiu

Assistant Professor, Delft University of Technology:Dr. Zhao Yifeng

Ultra-lean Silver Screen Printing

Senior Research Associate, University of New South Wales, Sydney (UNSW):Ran Chen

AIKO:Christian Peter

19:00 – 23:00

Dinner

9:00 – 9:45

5. BC wafer and cell production

Why Will Crystal Silicon xBC Solar Cells be Highly Promising?

Solar Energy Research Institute (SJTU):Prof. Dr. Wenzhong Shen

Advanced Laser Technology Empowering Next-Generation Back-Contact PV Manufacturing

Vice President of Sales & Marketing, DR Laser:Ben Lee

Gokin Solar :Jun Wang

Chief Scientist of Simulation and AI, Laplace :FaJun Ma

Next Generation PECVD

Centrotherm International AG:Helge Haverkamp

9:45 – 10:45

Break

10:45 – 12:15

6. BC module and material production

ISC Konstanz:Andreas Halm

SPIC:Gao JiaQing

Innovation on High-Efficiency HPBC Technology

LONGi Green Energy:Dr. Heng Sun

High quality glass for Photovoltaic, from monofacial to bifacial modules

SLMB:Dr. Rino MESSERE

AE Solar:Hamed Hanifi

12:00 – 14:00

Lunch

14:00 – 15:15

7. Evaluation and Quality

Quokka:Dr. Andreas Fell

Beyond Efficiency: A Deep Dive into the Performance and Reliability of BC Modules

TÜV Rheinland Group:Dr. Christos Monokroussos

PV Lighthouse :Dr. Malcom Abbott

15:15 – 16:00

Break

16:00 – 17:15

8. PV systems: application and safety

Futura Group:Francesco Fanti

AIKO:Shuai Wang

ODTÜ GÜNAM:Raşit TURAN

FINAL DISCUSSION, CLOSING AND NEXT BIFIPV WORKSHOP

ISC Konstanz:Radovan Kopecek

Leading the High-Quality Development of the PV Industry

BC Innovation Ecosystem Forum

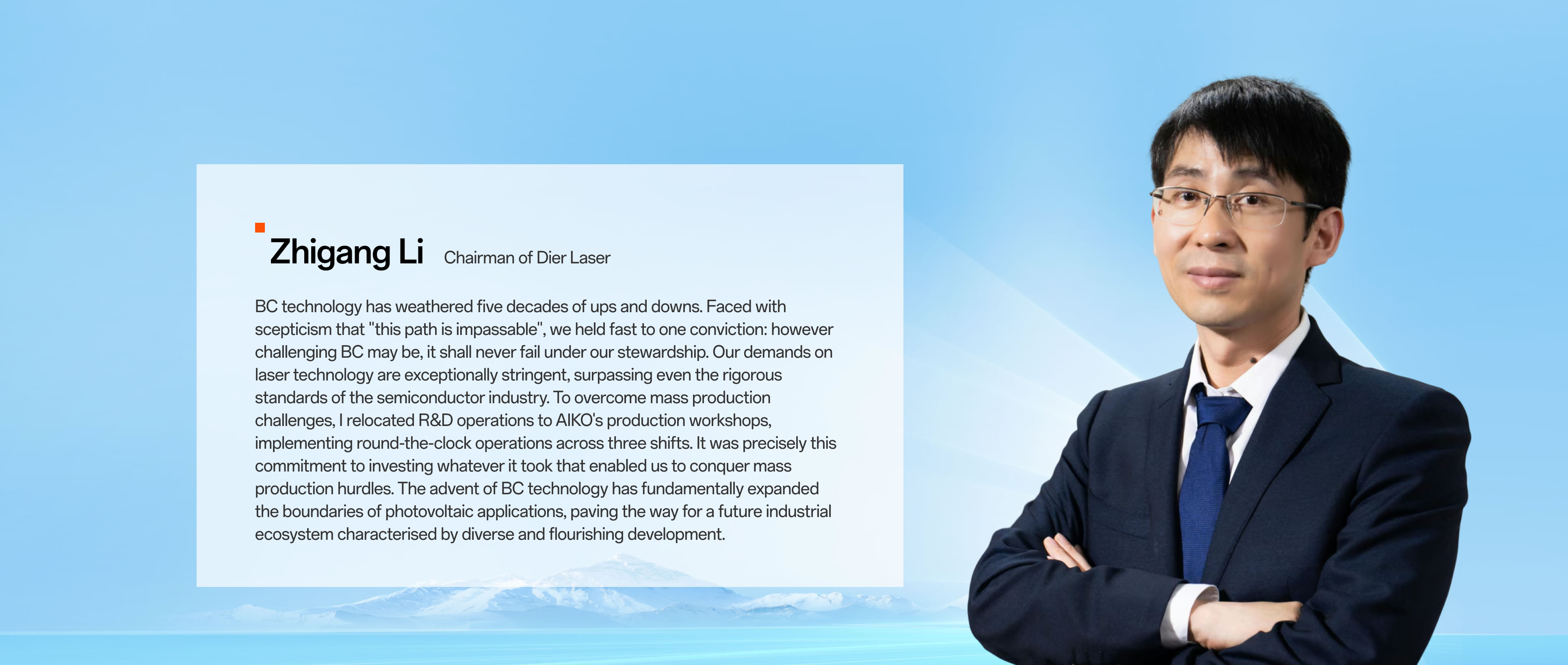

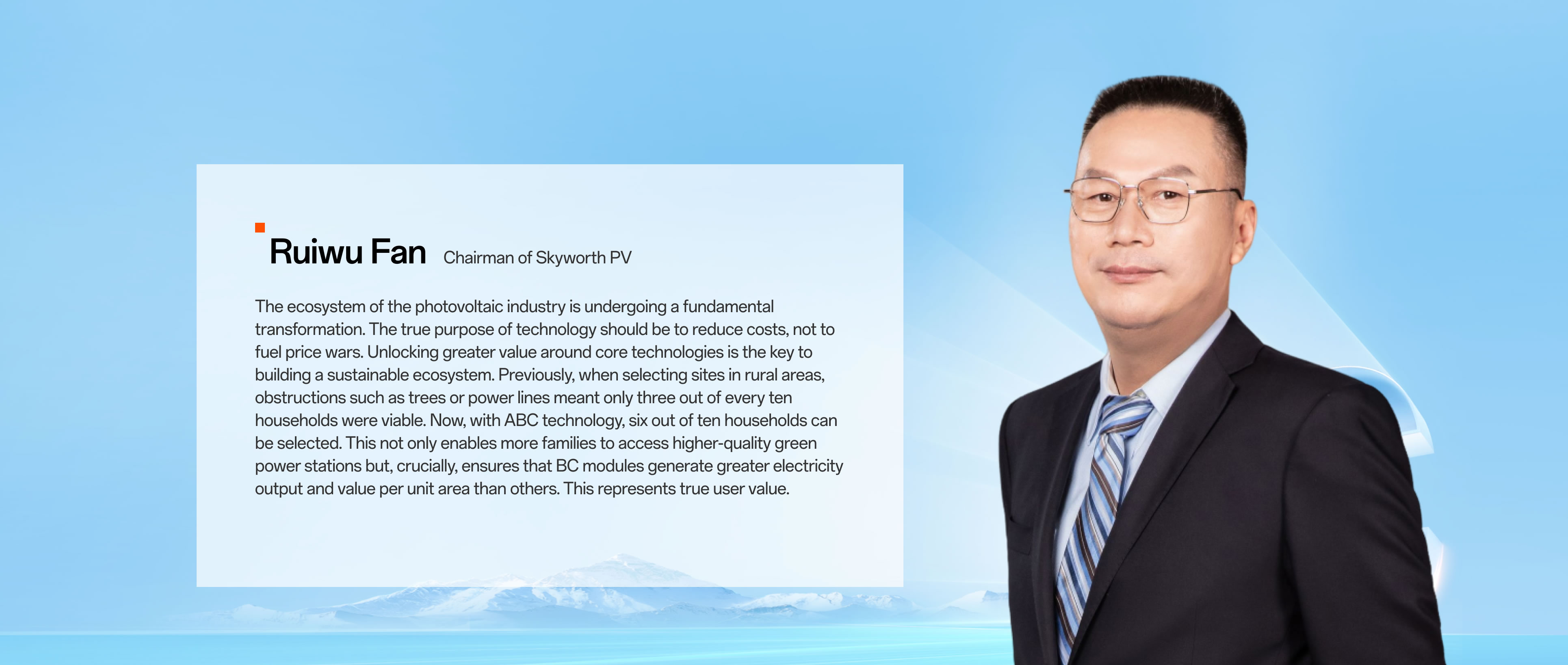

Chen Gang, Chairman of AIKO , Li Zhigang ,Chairman of DR Laser , Fan RuiWu Chairman of Skyworth PV, Li Weichun, Vice President of Global Power Electronics Product Services of TÜV Rheinland, RongBing Xia, Deputy General Manager of Laplace, FengaAn ,Gao Executive Managing Director of Rainbow New Energy, and Lv Fang, Secretary-General of the Photovoltaic Specialised Committee of the China Green Supply Chain Alliance,

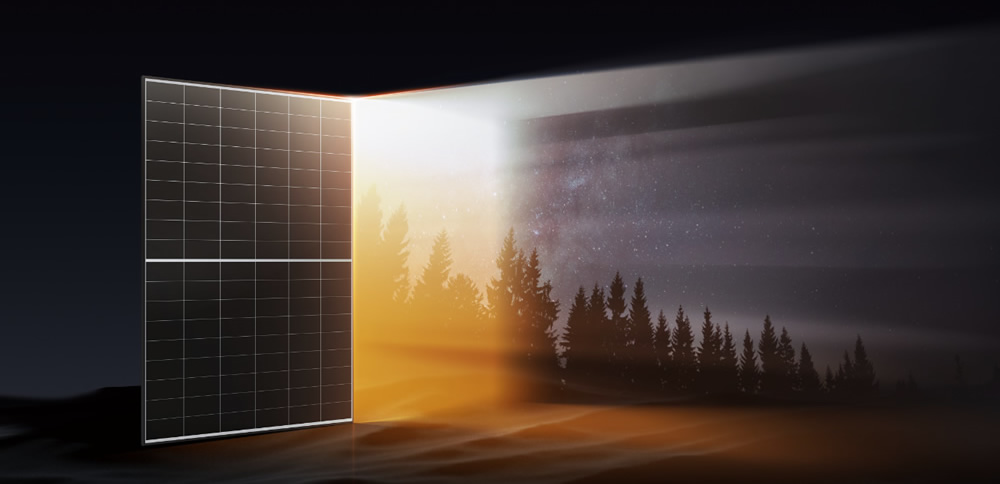

gathered together to discuss BC. They deliberated on the value, advantages, and future prospects of BC technology, unanimously agreeing that BC represents the most cost-effective and competitive crystalline silicon technology route currently available, constituting the optimal technical approach within the crystalline silicon pathway.

BC Technology: The Next Big Thing is Here

Round Table Forum

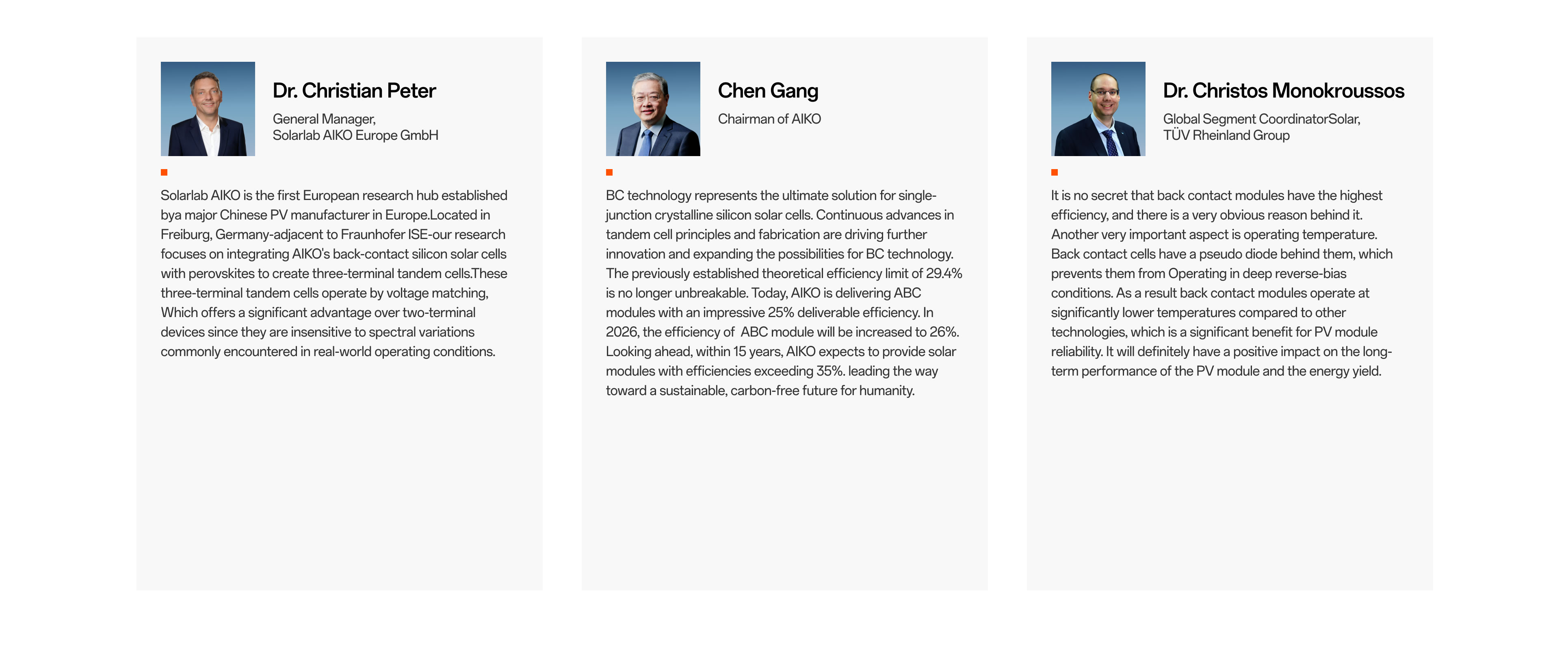

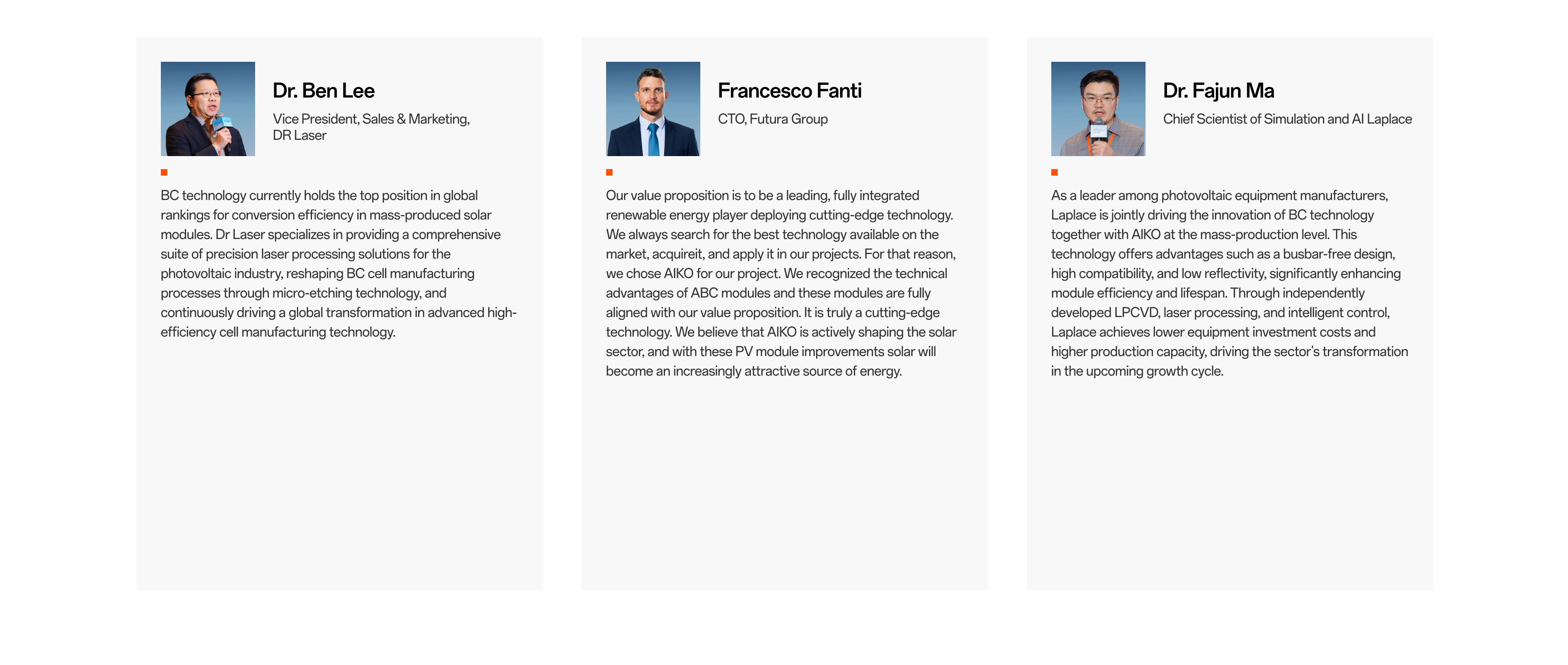

The panel featured Dr. Yongqian Wang, Chief Scientist of AIKO; Dr. Hongbo Tong, President of The First Research Institute at LONGi; Prof. Dr. Peter Fath, CEO of RCT Solutions GmbH; and Dr. Gianluca Coletti, CTO of the FuturaSun Group, and moderated by Min Ge, Co-founder of TaiyangNews. The discussion highlighted BC’s superior value proposition, anchored not only in higher efficiency but also in greater reliability, safety, and a lower Levelized Cost of Energy (LCOE). While acknowledging current cost challenges, the panelists outlined a clear path for BC’s expansion beyond premium rooftops into utility-scale markets. They emphasized that success hinges on continued manufacturing innovations to improve yield and reduce costs,

alongside robust supply chain collaboration.

TÜV Rheinland: Certification Ceremony for

PV Module Anti-Ignition Hazard

PV Module Anti-Ignition Hazard

Voices from the Summit

Co-organized by International Solar Energy Research Center Konstanz (ISC Konstanz) and AIKO, the summit attracted over 600 leading research scholars, technical experts, and top managers from prominent PV companies and institutions worldwide, marking a significant milestone in the advancement of back contact (BC) technology. The summit served as a platform for in-depth exchanges among companies and institutions specializing in silicon materials, wafers, cell and module R&D, manufacturing, testing, and system integration.